Plastic corner protectors are a widely used protective tool in packaging, transportation, and storage. They effectively prevent goods from being damaged by collisions and scratches during handling and storage. They not only protect the corners of items but also enhance the stability and load-bearing capacity of packaging boxes. To ensure that plastic corner protectors provide maximum protection, mastering the correct usage techniques and precautions is crucial. This article will guide you through the usage techniques and common precautions for plastic corner protectors, helping you better utilize this protective tool.

1. Basic Functions of Plastic Corner Protectors

Plastic corner protectors are corner protection tools made of high-strength plastic materials, commonly used in packaging, transportation, and stacking. Their main functions include:

Protecting item corners: By fixing the corner protectors to the corners of packaged items, they prevent damage caused by external impacts or friction.

Enhancing stability: Plastic corner protectors provide additional support to packaging boxes or pallets, preventing items from tilting or collapsing during stacking.

Improving load-bearing capacity: When items are stacked, plastic corner protectors distribute the load, reducing the risk of items being crushed, thereby increasing the load-bearing capacity during transportation and storage.

2. Choosing the Right Plastic Corner Protectors

Before using plastic corner protectors, it's essential to choose the appropriate type of protector. Different protector designs and materials are suitable for different items and environments. Here are some factors to consider when choosing the right plastic corner protectors:

Material type: Common plastic corner protector materials include polypropylene (PP), polyethylene (PE), and polystyrene (PS). When choosing a material, consider the weight of the goods, transportation distance, and environmental conditions. PP material is durable and has high impact resistance, suitable for heavier items; PE material is lighter and suitable for lighter goods.

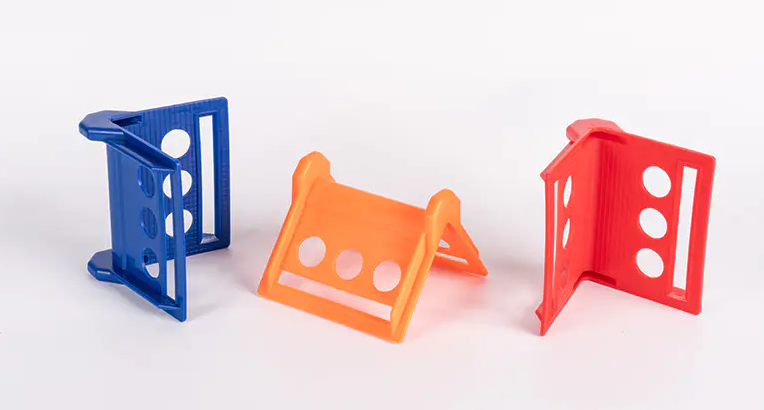

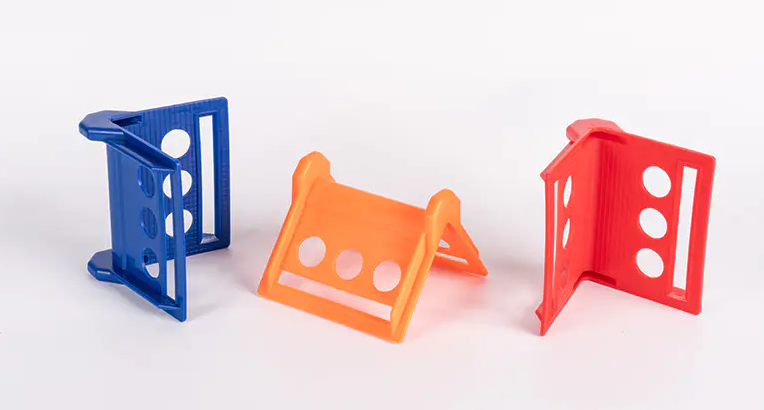

Protector shape and size: Plastic corner protectors usually come in L-shaped, U-shaped, and right-angled shapes. When choosing, match the shape of the protector to the shape of the item. The size should ensure that the protector completely covers the corners of the item to provide comprehensive protection.

Load-bearing requirements: Choose protectors with sufficient load-bearing capacity based on the weight of the items and the stacking method. For example, heavy items should use thicker protectors, while lighter items can use thinner ones.

3. How to Properly Install Plastic Corner Protectors

Proper installation of plastic corner protectors maximizes their protective function. Here are some installation tips:

Ensure the corners are clean and tidy: Before installing the corner protectors, first clean the corners of the item, removing dust, dirt, and other debris to ensure the corner protectors adhere firmly to the item.

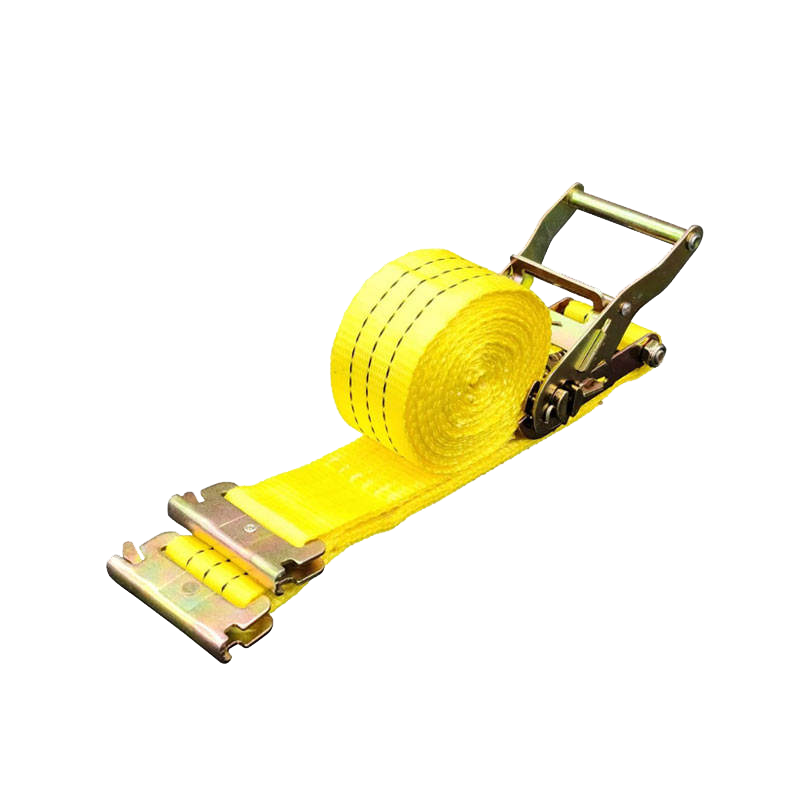

Properly secure the corner protectors: During installation, use tape, strapping, or stretch film to secure the plastic corner protectors to the corners of the item, ensuring they do not slide or fall off during transportation. Especially when stacking goods, ensure the corner protectors are stable to prevent displacement during transport.

Avoid excessive compression: When strapping or securing the corner protectors, avoid compressing them too tightly, as this may cause them to crack or deform. Maintain appropriate tension to ensure the corner protectors protect the item without damaging themselves.

4. Precautions During Stacking and Handling

Stacking and handling are also crucial aspects when using plastic corner protectors. Reasonable stacking and handling methods can extend the lifespan of the corner protectors and items, reducing the risk of damage during transportation:

Reasonable stacking of goods: When stacking items, ensure that the bottom layer of goods can evenly bear the weight of the upper layers. Overly heavy stacking will prevent the corner protectors from providing sufficient support, leading to deformation of the corner protectors or packaging boxes. Therefore, the number of stacking layers should be reasonably allocated according to the weight of the items.

Avoid violent collisions: During handling, try to avoid violent impacts and drops, as this will damage the plastic corner protectors and render them ineffective. When using forklifts or hand trucks, ensure smooth operation to avoid impacting the packaged items.

Pay attention to protecting the corners: Try to avoid direct contact with the corners of the goods, especially metal items, to prevent metal friction from damaging the corner protectors.

5. Common Application Areas of Plastic Corner Protectors

Plastic corner protectors have a wide range of applications in various industries, especially playing an important role in the following areas:

Logistics and transportation: In long-distance and domestic transportation, plastic corner protectors can be used to protect fragile items, reducing damage and friction during transportation. Warehousing and Storage: In warehouses, plastic corner protectors can be used to stack goods, improving the stability and safety of items and preventing damage caused by improper stacking.

Furniture and Building Materials Industry: For fragile items such as furniture and building materials, plastic corner protectors can prevent items from being damaged during transportation and handling, avoiding breakage.

Electronics and Electrical Products: The casings of electronic products and appliances are susceptible to external impacts. Plastic corner protectors can effectively reduce damage caused by collisions, ensuring product safety.

6. Frequently Asked Questions (FAQ)

Q1: Can plastic corner protectors protect all items?

A1: Plastic corner protectors are suitable for various packaged items, especially those with vulnerable corners. For very hard or fragile items, other types of protective measures may be needed, such as foam packaging or wooden corner protectors.

Q2: Can plastic corner protectors be used for outdoor transportation?

A2: Yes, plastic corner protectors have strong impact resistance and weather resistance, making them suitable for outdoor transportation. However, under extreme weather conditions (such as high temperatures or strong ultraviolet radiation), corner protector materials with higher weather resistance may be required.

Q3: How to clean plastic corner protectors?

A3: Plastic corner protectors can be cleaned with water and a neutral detergent to remove surface dust and stains. Avoid using strong acids or alkalis, as this may damage the surface of the corner protectors.

Q4: Can plastic corner protectors be reused?

A4: Plastic corner protectors can usually be used multiple times, provided they are not damaged or deformed. If the corner protectors show cracks or damage, it is best to replace them with new ones to ensure the protective effect.

Plastic corner protectors, as an important protective tool in packaging, transportation, and storage, can effectively reduce damage to items during handling and improve transportation efficiency and safety. Choosing the appropriate type of corner protector, proper installation, and correct use are key to ensuring their full protective function.