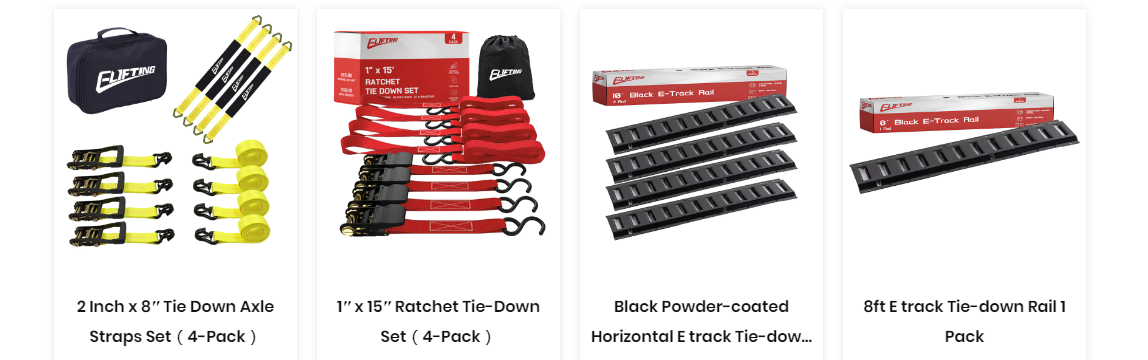

2" X15" Ratchet Strap Tie Down 5000lb J Hook

Cat:2 Inch Ratchet Straps

The ingenious ratchet buckle mechanism makes tightening and releasing the strap a breeze. Simply thread the strap through the buckle, pull the webbing...

See DetailsWith increasing transportation volume and the diversification of cargo types, ensuring the stability and safety of goods during transportation has become a crucial issue. E-Track rails, as an efficient and flexible cargo securing system, are increasingly being used in warehousing and transportation. They not only improve the efficiency of cargo transportation but also effectively reduce the risk of cargo damage, ensuring transportation safety.

1. What are E-Track Rails?

E-Track rails are a rail system specifically designed for securing cargo, widely used in cargo transportation and warehousing management. Their "E"-shaped rail structure allows cargo to be secured using specialized locks and other accessories, achieving robust cargo protection. E-Track rails can be combined with transport vehicles or warehousing equipment through various connection methods to ensure that cargo does not slip or tilt during transportation. Their simple and effective design allows for flexible adjustment according to different transportation needs, making them suitable for various industries and scenarios.

E-Track rails are typically made of durable metal materials (such as steel and aluminum alloys), possessing strong load-bearing capacity and corrosion resistance, making them suitable for transporting heavy cargo. Its structure typically includes components such as tracks, latches, accessories, and slides. All these parts work together to ensure that goods are stably secured during transportation.

2. How does the E-type track improve the safety of cargo transportation?

(1) Enhanced Cargo Fixing Force

The most significant feature of the E-type track is its ability to provide strong cargo securing. Through specialized latches and fixing devices, the E-type track can firmly secure cargo, preventing displacement and collisions during transportation. Especially in long-distance transportation or under harsh road conditions, if cargo is not properly secured, it may shift, tilt, or even be damaged due to vibration or bumps. The E-type track, through its effective fixing system, reduces this risk and ensures the stability of cargo throughout the transportation process.

(2) High Adaptability and Flexible Configuration

The E-type track can be flexibly configured according to different types of cargo and transportation needs. The length, spacing, and accessories of the track can be adjusted according to the size and weight of the cargo, allowing the E-type track to adapt to cargo of various shapes and sizes. Whether it is large equipment, heavy cargo, or irregularly shaped items, the E-type track can provide precise fixing and protection, ensuring safety during transportation.

(3) Reduced Collision and Friction

In cargo transportation, especially when transporting multiple goods, collisions and friction between goods can lead to surface damage or internal malfunctions. E-tracks, through precise positioning and isolation structures, effectively prevent direct contact between goods. In this way, E-tracks not only prevent collisions but also reduce damage caused by friction, extending the service life of the goods.

(4) Improved Transportation Efficiency

The stable securing of goods is not only related to safety but also closely linked to transportation efficiency. Traditional securing methods may require tedious binding work or repeated adjustments. The use of E-tracks greatly simplifies the securing process. Goods can be quickly secured using the tracks and accessories without complex operations. This not only saves time but also reduces human error, ensuring that goods are secured in the shortest possible time, thereby improving the efficiency of the entire transportation process.

(5) Enhanced Loading and Unloading Efficiency and Safety

After the goods arrive at their destination, E-tracks also improve loading and unloading efficiency. Since the goods are secured during transportation, the tracks can be quickly unlocked and disassembled during unloading, reducing the complexity of manual operations. More importantly, the structural design of the E-type track helps prevent goods from falling due to shaking or instability during unloading, thus improving the safety of loading and unloading operations.

(6) Durability and Stability

E-type tracks generally use high-strength metal materials, such as steel or aluminum alloys. These materials have extremely high durability and corrosion resistance, enabling them to be used for extended periods under various environmental conditions. Even in high-temperature, humid, or highly corrosive environments, the E-type track maintains stable performance, ensuring the safety of cargo transportation is unaffected by external environmental factors.