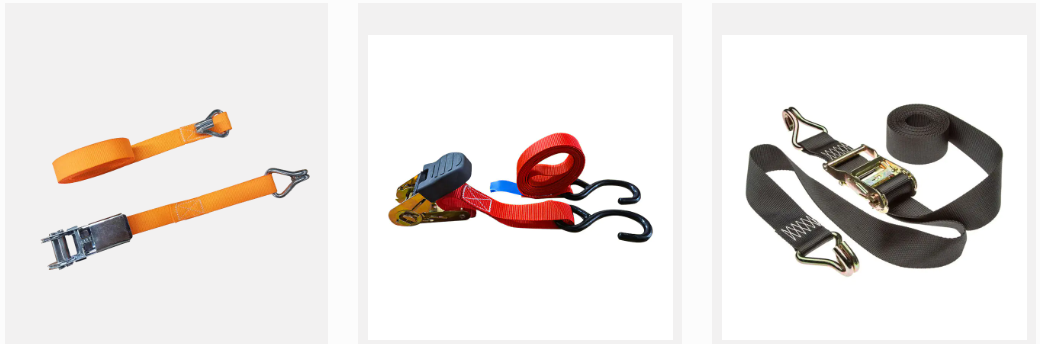

1" X 20" Ratchet Tie Down With S hook

Cat:1″Ratchet Straps

Crafted from high-grade polyester webbing and robust steel or plastic ratchet buckles, our 1" x 20' ratchet strap can withstand even the demanding tas...

See DetailsStraps and binding tools play a crucial role in securing, handling, and transporting various items. Traditional straps (such as nylon and polyester straps) are widely used in many industries and fields, but with technological advancements, ratchet straps have gradually become a more advanced and efficient option. Especially in logistics, warehousing, automotive transportation, and the handling of heavy equipment, ratchet straps, due to their unique design and performance advantages, have gradually replaced traditional straps, becoming a safer and more reliable securing tool. So, what are the specific advantages of ratchet straps compared to traditional straps?

1. Structure and Working Principle of Ratchet Straps

A ratchet strap is a strap system that integrates securing, tensioning, locking, and releasing functions. It consists of a strap body, ratchet, tensioning device, and hooks. The core component of a ratchet strap is the ratchet mechanism, which utilizes the interaction between the ratchet and its teeth to tension the strap when it is slack by rotating the ratchet, and effectively locks the strap to prevent loosening. When the belt needs to be loosened, it can be easily released by operating the ratchet mechanism, facilitating disassembly and reuse.

2. Advantages of Ratchet Belts

(1) Stronger Tension

Compared to traditional straps or elastic bands, ratchet belts offer stronger tension. The ratchet mechanism provides continuous tension, resulting in a more secure fixation and the ability to withstand higher pressure and loads. Whether during transportation or long-term storage, ratchet belts effectively prevent items from loosening or shifting, ensuring safety during transport.

When transporting large items or heavy machinery, traditional belts may cause items to shift or even become dangerous due to insufficient tension over time or belt elongation. The tension of ratchet belts can be adjusted by rotating the ratchet, ensuring a more secure fixation and effectively reducing risks during transportation.

(2) Easy to Operate and Adjust

Operating ratchet belts is very simple; users can easily adjust the belt tension by rotating the ratchet. Ratchet mechanisms automatically tension the belt and secure it with a locking mechanism, enabling rapid and precise adjustments even in complex working environments.

In contrast, traditional belts typically require manual pulling and securing with knots or hooks during tensioning, a cumbersome process prone to loosening or unevenness. This is especially inefficient and laborious in situations requiring repeated adjustments. Ratchet belts, with their integrated ratchet mechanism, reduce the need for manual operation, improving efficiency and operational safety.

(3) Enhanced Safety

A key advantage of ratchet belts is their superior safety. When transporting heavy objects, traditional belts often cause items to loosen or even slip due to uneven tension or insecure securing. This is particularly problematic during vehicle operation, where goods may shift due to vibration and bumps, creating safety hazards.

However, ratchet belts, with their ratchet locking function, maintain continuous pressure, preventing loosening or slippage. Under load, ratchet belts can effectively withstand significant tension, avoiding the risk of item displacement and accidents. Furthermore, the ratchet belt is equipped with safety hooks or buckles, further enhancing the securing effect and greatly improving safety during use.

(4) High Durability and Long Service Life

Ratchet belts are typically made of high-strength materials (such as polyester or nylon), possessing high abrasion resistance and tensile strength. Therefore, even in harsh environments (such as high humidity, high temperature, or low temperature), ratchet belts can maintain stable performance for a longer period, extending their service life.

In contrast, traditional belts may wear down, loosen, or even break after repeated use, especially under prolonged heavy loads. The design and materials of ratchet belts make them more durable, capable of withstanding greater tensile forces, reducing the need for frequent belt replacements and saving on long-term maintenance costs.

(5) Easy Storage and Transportation

Ratchet belts typically have a compact design, allowing them to be easily rolled up and stored in a small storage box. In contrast, traditional belts often become messy after use and are inconvenient to store. The efficient design of ratchet belts allows them to occupy less space during storage and transportation, facilitating handling and storage.

Especially in situations requiring the carrying of multiple tools or accessories, ratchet straps offer easy storage without taking up much space. This is particularly important for industries such as logistics and transportation, and handling companies, as it improves work efficiency and reduces time wasted due to tangled straps.

(6) Wide Range of Applications

Ratchet straps have a very wide range of applications, suitable for transporting goods of various weights and sizes. They offer great flexibility, especially when transporting large machinery, furniture, appliances, automobiles, and other bulky items. Traditional straps are generally suitable for binding light goods or smaller items, while ratchet straps are even more advantageous for items requiring high-strength fixation.

Furthermore, ratchet straps can be used with various types of hooks, connectors, and clamps, making them more adaptable and able to meet the needs of different work scenarios.

In general, compared to traditional straps, ratchet straps have significant advantages in tension, ease of operation, safety, durability, and convenient storage. With its unique design, ratchet straps provide a more stable and secure fixation effect, avoiding the loosening and safety issues that may exist with traditional straps. Furthermore, ratchet belts can improve work efficiency and reduce manual operations, making transportation and handling more efficient and safer. Therefore, ratchet belts are gradually becoming an indispensable tool in the transportation, warehousing, and automotive industries.