1" X 20" Ratchet Tie Down With S hook

Cat:1″Ratchet Straps

Crafted from high-grade polyester webbing and robust steel or plastic ratchet buckles, our 1" x 20' ratchet strap can withstand even the demanding tas...

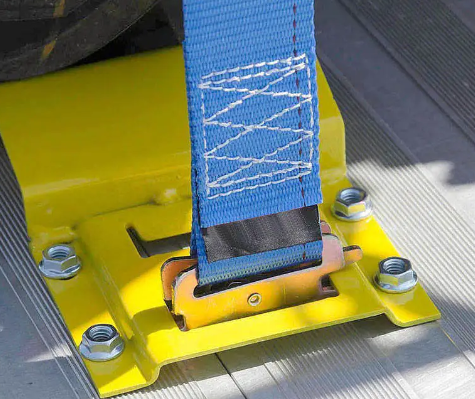

See DetailsThe E-track ratchet tiedown (also known as an E-track ratchet strap or E-track cargo control system) is a cargo securing device designed for trucks, containers, or trailers. It is primarily used to quickly and securely tie and secure cargo during transport, preventing it from shifting, tipping, or being damaged.

Secures Cargo: The ratchet mechanism tightens the straps, securely securing cargo (such as boxes, pallets, and machinery) to the truck's E-track, preventing it from sliding or colliding during transport.

Compatible with E-track Systems: Designed to work with E-track rail slots on the side or floor of the truck, hooks or sliders snap into the rails, enabling multi-point securing and high flexibility.

Quick Operation: The ratchet mechanism allows the user to gradually tighten the straps, eliminating the need for complex tools and enabling a single operator to perform the operation, saving time and effort.

Enhanced Transport Safety: Prevents cargo from shifting due to bumps, sudden braking, or cornering, reducing the risk of accidents and complying with logistics safety regulations.

Core Components

Ratchet Handle: Used to tighten or release the strap, typically with a self-locking feature.

Strap (Webbing): Made of high-strength polyester or nylon, typically 1-2 inches wide and abrasion-resistant.

E-Track Hook: A metal hook that slides into the E-Track slot to secure the ratchet end or strap end.

End Hook: Used to secure the other end of the strap (such as the other side of the track or the cargo itself).

Applications

Truck/Trailer Transport: Such as vans, flatbeds, and containers.

Heavy Equipment: Secures machinery, construction materials, and vehicles.

Logistics and Warehousing: Utilizes the E-Track system for modular cargo management.

Advantages of E-Track Ratchet Tiedowns

Compatible: Compatible with standard E-Tracks and can be combined with other E-Track accessories (such as chains and ropes).

High Load Capacity: A single strap can typically hold 500-5000 pounds (depending on specifications).

Adjustable: Flexible strap length adjustment accommodates cargo of varying sizes.

Common Problems with E-Track Ratchet Tie-Downs

Cause:

The strap is not properly inserted into the ratchet mechanism.

The gears inside the ratchet are worn or damaged.

The strap is too thick or made of too hard a material, causing the gears to not engage properly.

Solution:

Reinsert the strap, ensuring it is fully engaged in the ratchet groove.

Replace damaged ratchet components or replace the tie-down entirely.

Use straps of standard thickness/material (such as polyester).

Cause:

The ratchet handle is not fully returned to the "release" position.

The strap is overtightened, causing the gears to bind.

Rust or dirt has accumulated inside the ratchet.

Solution:

Push the handle firmly to the fully released position before pulling the strap.

Gently rock the handle in the opposite direction to release the gears.

Clean and lubricate the ratchet mechanism (use a silicone-based lubricant).

Cause:

The hook is not fully engaged in the E-track groove.

The E-track groove is deformed or worn.

The hook size does not match the track (e.g., non-standard E-track hook).

Solution:

Check that the hook is fully engaged in the track to ensure it is locked in place.

Replace any damaged track or hook.

Cause:

Overloading (exceeding the strap's rated load).

The strap is aged, worn, or in contact with sharp edges.

Prolonged UV exposure causes material degradation.

Solution:

Select a strap with a higher load rating (e.g., 2-inch wide, 5,000-pound load capacity).

Use corner guards or edge protectors to prevent cuts.

Inspect the strap regularly and replace any old straps that are cracked or have loose fibers.

Cause:

The internal spring is defective or rusted.

The strap is too tight, causing excessive handle resistance.

Solution:

Lubricate the ratchet mechanism or replace the spring.

Tighten the straps in sections to avoid applying too much force at once.