In the logistics and transportation industry, the safe and stable transportation of heavy cargo is a crucial aspect. Ratchet tie-down straps (also known as ratchet straps or ratchet ties) are a highly efficient binding tool widely used in the transportation of heavy cargo. Their unique structural design and excellent performance make them an ideal choice for ensuring the safe transport of goods. So, what are the advantages of ratchet tie-down straps? Why have they become an important piece of equipment in the transportation of heavy cargo?

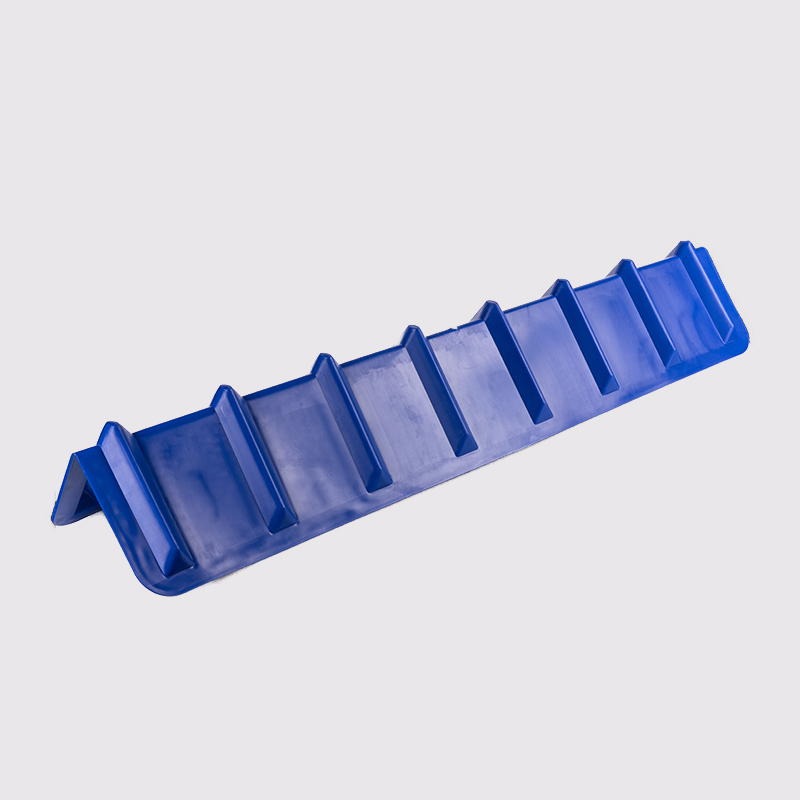

Ratchet tie-down straps consist of a roll of strap with a ratchet mechanism, metal fasteners, and a tension adjustment device. During use, the strap tightly secures the cargo through the ratchet mechanism, and the mechanical advantage of the ratchet keeps the strap taut, preventing displacement or swaying of the cargo during transportation. The ratchet design allows the strap to withstand significant tensile force for extended periods without loosening, ensuring the stability of the cargo.

2. Advantages of Ratchet-Type Tie-Ups for Heavy Goods Transportation

(1) Strong Tensioning Capacity

The most significant feature of ratchet-type ties is their strong tensioning force. Compared to ordinary ties, the ratchet mechanism achieves a very tight bond through repeated turning and locking, adapting to the transportation needs of various heavy goods. For large machinery, automotive parts, or other heavy objects, ordinary ties often cannot provide sufficient securing force, while ratchet-type ties can tighten to their maximum extent in a short time, ensuring that the goods do not loosen.

(2) Reliable Fixing Effect

Ratchet-type ties use a ratchet locking mechanism, which is self-locking, ensuring that the ties will not loosen even during long-term transportation. Due to its unique design, the ratchet device can effectively resist vibration and external impact, preventing the ties from loosening due to changes in the external environment. Especially in long-distance transportation, the self-locking function of ratchet-type ties ensures that the goods remain safe and fixed, reducing accidents caused by loose binding.

(3) High-Strength Materials

Ratchet straps are typically made of high-strength polyester (PET), nylon, or other synthetic fiber materials. These materials not only have high tensile strength but also strong corrosion resistance and UV resistance. Even in harsh environments, ratchet straps maintain stable performance. Especially in high-temperature, humid, and even acidic/alkaline environments, the high durability of ratchet straps effectively ensures the safe transport of heavy goods.

(4) Easy to Use and Adjustable

Ratchet straps are very easy to use; even inexperienced operators can quickly get started. Simply wrap the strap around the goods, tighten it, and secure it with the ratchet mechanism. Compared to traditional straps, ratchet straps eliminate the tedious binding process, saving significant time and labor costs. Furthermore, the ratchet tension is easily adjustable, allowing for adjustments to the strap's tightness based on the volume and weight of the goods, ensuring cargo stability.

(5) Preventing Cargo Movement and Damage

When transporting heavy cargo, especially fragile items such as glass, electronic components, and precision equipment, the stability of ratchet straps is crucial. Through strong tension and precise securing, ratchet straps effectively prevent displacement or damage to cargo during transport due to vibration, collisions, or other factors. Furthermore, the width and material flexibility of the straps themselves help distribute the binding force, preventing excessive pressure on the cargo surface and reducing potential damage during transport.

(6) High Safety

Through a reasonable design, ratchet straps can apply uniform tension to the cargo during transport, preventing damage caused by excessive pressure on any part of the cargo. Moreover, the ratchet system itself has a self-locking function, making it less prone to loosening due to human error or external forces, increasing transport safety. Compared to other binding methods, ratchet straps can significantly reduce the risk of accidents caused by insecure binding, such as cargo slippage or loss of control of the transport vehicle.

Ratchet straps are widely used in the transportation of various heavy goods, particularly suitable for the following situations:

Logistics Transportation: In long-distance freight transportation, especially for heavy equipment, machinery parts, and building materials, ratchet straps provide a reliable securing solution, ensuring the stable and safe arrival of goods at their destination.

Container Transportation: Ratchet straps are widely used in container transportation to secure bulk or irregularly shaped goods, preventing displacement during transport.

Road and Rail Transportation: During road or rail transportation of heavy goods, ratchet straps can be used to secure goods inside trucks or train carriages, reducing shaking and collisions during transport.

Marine Transportation: For heavy goods transported by sea, the corrosion resistance and UV resistance of ratchet straps make them a commonly used securing tool in maritime transport, capable of withstanding the harsh marine environment.

Ratchet straps play a vital role in the transportation of heavy goods due to their excellent fastening ability, reliable securing effect, and high-strength materials. It not only enhances cargo safety and reduces the risk of damage during transportation, but also improves work efficiency and saves time and labor costs. As the logistics industry continues to demand higher levels of safety and efficiency in transportation, ratchet-type straps will have an even broader application prospect, becoming an important tool in modern logistics transportation.