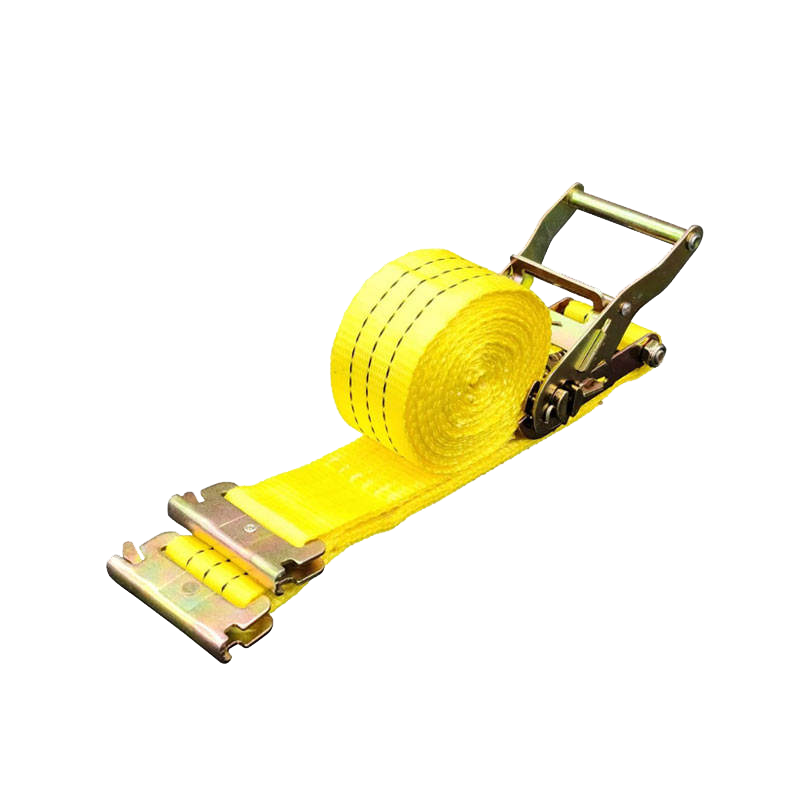

Tie Down Straps Set (also known as strapping, cargo securing straps) is a common tool for securing cargo during transportation, moving, or outdoor activities. Proper use can prevent cargo from shifting, falling, or being damaged. Tie Down Straps Set ensures that items remain safe and stable during transportation. Whether moving furniture or tying cargo to trucks and trailers, this set of straps can provide reliable fastening performance.

1. Steps and methods for securing cargo

(1). Preparation

Inspect the straps: Make sure the straps are not worn or broken, and the metal buckles/ratchets are functioning properly.

Plan the fixing points: Select a strong anchor point on the vehicle/cargo box (such as a truck hook ring, trailer D-ring).

Cargo stacking: Place the cargo compactly to avoid loose or sharp edges (add non-slip cloth or foam padding).

(2). Basic fixing methods

1) Horizontal tying (to prevent left and right movement)

Wrap the straps around the top of the cargo and secure the ends to the anchor points on both sides of the vehicle. Use a ratchet or buckle to tighten the straps, ensuring they are tight and free of slack.

Applicable for: Horizontally securing boxes, furniture, and equipment.

2) Longitudinal Tiedowns (Prevent Forward and Backward Movement):

Wrap the straps from the front of the cargo to the rear and secure them to anchor points on the front/rear of the vehicle.

Suitable for long cargo (such as lumber and pipes).

3) Cross Tiedowns (Increased Stability):

Use an "X" or "#" pattern to cross-secure the cargo to reduce sway.

Applicable for: Motorcycles, heavy machinery, and irregularly shaped cargo.

4) Elastic Cord Securing (Lightweight Cargo):

Secure the ends of the elastic cord with hooks and cross-wrap it around the cargo to increase friction.

Applicable for: Tents, awnings, and luggage.

2. Key Considerations:

Tension: The straps should be tight, but avoid excessive tension that could cause deformation or breakage (test by hand to ensure they remain firm).

Abrasion Protection: Add corner guards or felt to sharp edges of the cargo to prevent the straps from being cut. Avoid direct contact between strapping and metal edges; use rubber sheaths.

Regular Inspection: During long-distance transport, check the tightness every 2-3 hours and re-tighten if necessary.

No Overloading: Do not exceed the rated load capacity of the strapping (e.g., a 500kg strap cannot be used for 1 ton of cargo).

Avoid Sun Exposure: Prolonged UV exposure will weaken nylon/polyester strapping. Store in a cool, dark place.

3. Common Problems and Solutions

Tie-down straps won't tighten?

Check the ratchet for sticking, clean any dust, or lubricate the gears.

Is the cargo slipping?

Add anti-slip pads or use a cross-tying method.

Is the strap broken?

Replace with a higher-load-capacity model. Avoid using worn or aged straps.